- Home

- Managing An Irrigation System

- Planning System Hardware

- Farm Irrigation Systems & Cost Analysis

- Water Resource Development

- Micro Irrigation Handbook

- Related Links

The Hose Tow Irrigation System

Operational, Energy and Planning Requirements

Larry M. Curtis, Agricultural Engineer-Soil & Water

Ted W. Tyson, Agricultural Engineer-Irrigation

The operating pressure of a hose tow irrigation system is an important indicator of the energy requirements of the system. However, it is important to first understand how a hose tow system operates.

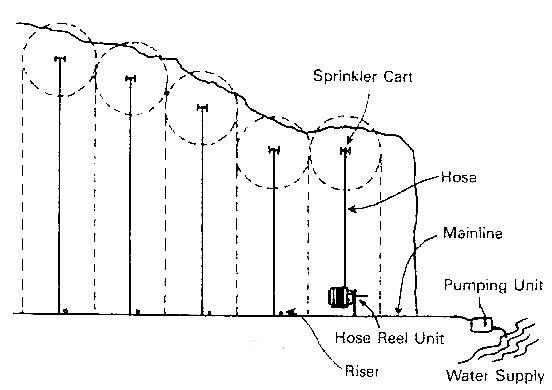

A typical hose tow traveler is shown in Figure 1. The hose tow traveler consists of the hose reel mechanism, a semi-rigid hose, and a sprinkler cart. The hose is wound on the reel and attached to the cart. Water from the pumping unit flows through the mainline, through risers located along the mainline, and into the hose reel. The water then flows through the hose and is discharged through a large sprinkler located on the sprinkler cart.

Operating A Hose Tow System

The operating procedure begins by attaching the hose reel to a riser. The sprinkler cart is then pulled to the far end of the field while the hose unwinds from the hose reel. The pumping unit is then started and water is pumped through the system. The hose reel slowly rewinds the hose and pulls the sprinkler cart through the field. The large sprinkler irrigates a rectangular strip that has a width equal to the effective sprinkler diameter and a length not greater than the length of the hose.

After one rectangular strip is irrigated, the pumping unit is stopped, the system is moved to an adjacent strip, and the procedure is repeated. This procedure is continued until all rectangular strips in the field are irrigated. If dry conditions continue, the procedure is repeated, beginning again with the first rectangular strip.

Hose tow units are available in a variety of sizes. Smaller units may irrigate 5 to 25 acres while larger systems may irrigate 50 to 100 acres.

The horsepower requirements for these systems vary considerably depending upon the size, site conditions, and design. The larger units often have from 75 to 150 horsepower (hp) requirements. Smaller units may have horsepower requirements as low as 7-1/2 hp.

Hose tow units require much labor and management. A unit must be moved frequently during a drought to effectively irrigate the entire field. The system, including the pumping unit, is often moved to water sources and field locations that are long distances apart.

Energy Requirements

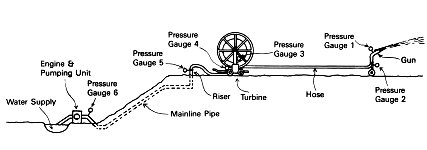

The energy or pressure requirements of a hose tow system are relatively large. In Figure 2, pressure gauges in a hose tow system are indicated at several locations and numbered 1 through 6.

When analyzing this type of system, it helps to begin with the large sprinkler attached to the end of the hose. Pressure gauge 1 indicates the pressure necessary for the gun to operate successfully. A pressure between 70 and 90 pounds per square inch (psi) is necessary for satisfactory water break-up and distribution.

The pressure difference between gauge 1 and gauge 2 represents a short lift of water from the hose attachment of the gun to the gun discharge. This pressure difference should be minimal, but some difference will occur due to the change in elevation and friction losses in the riser portion of the sprinkler. The pressure at gauge 3 indicates the pressure required just before the water enters the hose of the system.

Figure 1. Hose Tow Traveler.

A substantial pressure drop or change occurs between gauge 3 and pressure gauge 2. It is not uncommon for at least a 50-psi pressure drop to occur between these two points. This drop occurs because of the energy required to overcome friction in the hose.

Figure 2. Hose Tow Irrigation System.

Gauge 4 indicates the pressure just before the water enters the turbine of the hose tow system. This turbine requires energy from the water to operate the assembly that rewinds the hose. It is common for pressure differences of 55 to 60 psi to exist between gauge 4 and gauge 2. Thus, the pressure requirement at gauge 4 would be: gun pressure (85 psi) plus system loss (60 psi) equals 145 psi.

If a system was operating at a 500 gallon-per-minute flow rate and a pressure difference of 60 psi occurred between gauge 4 and gauge 2, and the pumping efficiency of the system was 65 percent, the horsepower required to simply move the water from gauge 4 to gauge 2 would equal about 27 hp.

The pressure at gauge 5 represents the pressure requirements as the water is discharged from an underground line into a line connecting the riser to the hose tow machine. Since this is generally a small diameter hose-4 or 4-1/2 inches-some pressure loss also occurs in this length of hose that connects the system to the underground pipe.

Gauge 6 represents the pressure at the discharge point of the pump. This is the sum of the pressure required to operate the sprinkler, the pressure required to overcome the frictional resistance to flow through the hose tow unit, the pressure required to overcome frictional resistance to flow in the mainline pipe, the pressure required to overcome the elevation difference between gauge 1 and gauge 6, and pressure losses due to such factors as fittings and turns.

The pressure at gauge 6 along with the additional head requirements for lifting water from the water source through the suction pipe and fittings to gauge 6 must be determined before selecting a pump and determining the total horsepower requirements of the system.

The total pressure or total dynamic head of an irrigation system is a major factor in determining the horsepower requirements of the system (1 psi = 2.37 feet of head). The following formula is used to determine the horsepower requirements of a pump:

Continuous Horsepower = Gallons Per Minute x Total Dynamic Head

3960 x Pump Efficiency

Systems that have a high total dynamic head will require more horsepower to pump water than systems that have a lower total dynamic head. Smaller engines or power units will cost less initially and will consume less energy per hour than larger units.

The hose tow system has many advantages over other portable systems, particularly where short runs are encountered and in setting up and moving the system from one location to another. However, the hose tow unit is one of the highest energy-consuming systems available, primarily due to large losses that occur in the hoses, fittings, and turbine mechanism. For this reason, discharge pressures at pressure gauge 6 are often 160 psi and may often be much higher if long pumping distances and large elevation changes are parts of the system's design. Because of these high pressures, you should carefully consider your pipeline design.

ANR-506 |

May 1988 |

Larry M. Curtis, Agricultural Engineer, Soil and Water

Ted W. Tyson, Agricultural Engineer, Irrigation |

Issued in furtherance of Cooperative Extension work in agriculture and home economics, Acts of May 8 and June 30, 1914, and other related acts, in cooperation with the U.S. Department of Agriculture. The Alabama Cooperative Extension System (Alabama A&M University and Auburn University) offers educational programs, materials, and equal opportunity employment to all people without regard to race, color, national origin, religion, sex, age, veteran status, or disability.

This document is author-produced (unedited).

Menu

Menu