- Home

- Managing An Irrigation System

- Planning System Hardware

- Farm Irrigation Systems & Cost Analysis

- Water Resource Development

- Micro Irrigation Handbook

- Related Links

The Cable Tow Irrigation System

Operational, Energy and Planning Requirements

Larry M. Curtis, Agricultural Engineer-Soil & Water

Ted W Tyson, Agricultural Engineer-Irrigation

The pressure required of a cable tow irrigation system is a good indicator of the energy needed to efficiently operate such a system. But before evaluating energy requirements, it is important to know how a cable tow system operates.

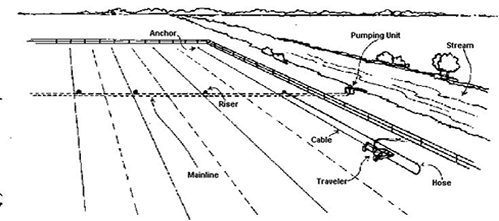

A typical cable tow system is shown in Figure 1. Water is delivered from the pump unit through an underground mainline pipe. The cable tow unit consists of a large sprinkler mounted on a mobile vehicle. This unit is connected to the water supply by a flexible hose that connects to risers located along the mainline. The mainline is typically installed through the center of rectangular strips that are twice the length of the flexible hose. A drum on the mobile vehicle contains a cable that is twice as long as the hose.

Figure 1. Cable Tow Traveler.

Operating A Cable Tow System

The procedure for operating a cable tow system begins by attaching the hose to a riser and unrolling the hose from a reel to one end of the field. The traveling sprinkler is set up at this point and the hose is attached. The cable is then unrolled from the drum to the far end of the rectangular strip and attached to an anchor. The pumping unit is then started.

Water flows through the mainline, out of a riser, into the hose, through the traveler, and out of the large sprinkler located on the traveler. As the water flows through the traveler, it passes through a turbine mechanism that turns the cable drum mechanism, thus rewinding the cable on the drum.

Since the cable was initially anchored, it pulls the traveler through the field, irrigating a rectangular strip that has a width equal to the effective wetted diameter of the sprinkler. The supply hose is dragged along with the traveler and is fully extended on the opposite side of the riser when all the cable is retrieved on the cable drum.

After a rectangular strip is irrigated, the pumping unit is stopped, the system is moved to an adjacent strip, and the procedure is repeated. This procedure is continued until all rectangular strips in the field are irrigated. If dry conditions continue, the procedure is repeated beginning again with the first rectangular strip.

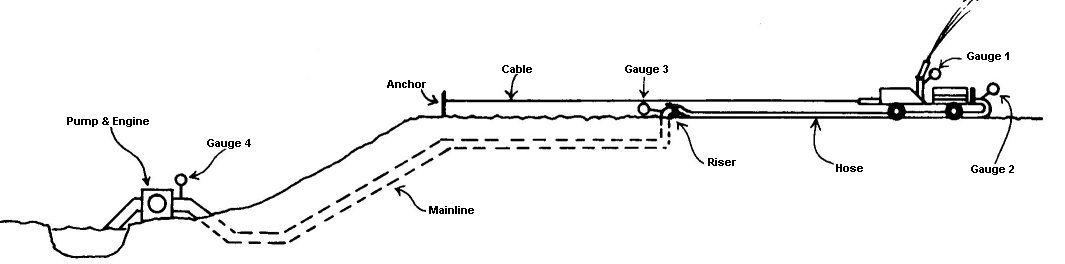

Figure 2. Cable Tow Irrigation System.

Energy Requirements

When evaluating a cable tow system, it helps to start at the sprinkler end of the system and look at the pressure requirements from that point back to the pumping unit. In Figure 2, pressure gauge 1 is located at the traveling gun sprinkler. The pressure at the sprinkler must be high enough to operate the gun successfully. In most cases, the pressure required at the gun is about 80 to 90 pounds per square inch (psi).

Gauge 2 represents the pressure going into the traveler unit. Most cable tow units have a hydraulic turbine that uses some water pressure to wind up the cable that tows the system through the field. Gauge 2 must read higher than gauge 1 to provide enough energy to retrieve the cable as well as to overcome the elevation and friction differences between 2 and 1.

The pressure at gauge 3 represents the pressure at the riser where the flexible hose is attached and extended to the traveler. Gauge 3 will read higher than gauge 2 because of resistance to the flow of water passing through the small flexible hose connecting the riser to the cable tow unit.

The pressure at gauge 4 is the sum of the pressure required to operate the gun; the pressure required to overcome the resistance to flow in the hose, pipe, fittings, and turbine; and the pressure required to overcome the elevation difference between gauge 4 and gauge 1.

The total dynamic head, or total pressure requirement of the system, is equal to the pressure at gauge 4 plus the pressure to overcome suction lift and suction friction.

The total pressure or total dynamic head of an irrigation system is a major factor in determining the horsepower requirements of the system (1 psi = 2.37 feet of head). The following formula is used to determine the horsepower requirements of a pump:

Continuous Horsepower = Gallons Per Minute x Total Dynamic Head 3960 x Pump Efficiency

Systems that have a high total dynamic head will require more horsepower to pump water than systems that have a lower total dynamic head. Smaller engines or power units will cost less initially and will consume less energy per hour than larger units.

Traveler irrigation systems are high-energy consumers when compared to other types of irrigation systems. This is because the end gun requires high pressure for operation and the flexible hose has a high pressure loss. Traveler systems are most often used in situations where fields are not suitable for center pivot systems and where portability is important.

A typical cable tow system delivers 500 to 550 gallons per minute. At this flow rate, about 50 acres can be effectively irrigated in a drought. The best use for a traveler system is on a manageable acreage of one crop such as corn and then on a second, later-maturing crop such as peanuts or cotton.

| Publication No.

ANR-508 |

Date

June, 1988 |

Larry M. Curtis, Extension Agricultural Engineer, Professor, Biosystems and Agriculture Engineering, and Ted W. Tyson, Extension Agricultural Engineer, Associate Professor, Biosystems and Agriculture Engineering. |

Issued in furtherance of Cooperative Extension work in agriculture and home economics, Acts of May 8 and June 30, 1914, and other related acts, in cooperation with the U.S. Department of Agriculture. The Alabama Cooperative Extension System (Alabama A&M University and Auburn University) offers educational programs, materials, and equal opportunity employment to all people without regard to race, color, national origin, religion, sex, age, veteran status, or disability.

This document is author-produced (unedited).

Menu

Menu