- Home

- Managing An Irrigation System

- Planning System Hardware

- Farm Irrigation Systems & Cost Analysis

- Water Resource Development

- Micro Irrigation Handbook

- Related Links

Efficient Irrigation Planning

Factors to Consider

Larry M.Curtis, Extension Agricultural Engineer

Ted W Tyson, Extension Agricultural Engineer

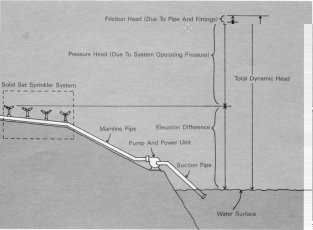

Irrigation is energy-intensive. If you are considering installing an irrigation system, carefully evaluate the energy required to operate the irrigation equipment. The cost of operating an irrigation system varies considerably depending on different factors: the elevation difference, the pipe and fittings, the system type, the pumping unit, the power unit, and the volume of water needed each season.

You should study these factors as you plan your irrigation system, before the system is designed and installed. Through careful planning, the most efficient system for your situation can be developed.

Elevation Difference

Elevation difference is the difference between the surface of the water supply and the sprinkler nozzle or other water-application device at the highest point in the field that is to be irrigated. The elevation difference can vary a great deal from one location to another.

For example, the depth to the water in a well could be relatively shallow in one location and several hundred feet in another. The water depth (including the drawdown during pumping) is added to the above-ground elevation to get the total elevation difference. The elevation difference from a lake or pond will depend on the difference between the water level in the pond and the highest point of the field to be irrigated.

Pipe And Fittings

The pipe and fittings used to connect the water source to the irrigation equipment also have an effect on the amount of energy required to supply water to the system.

Factors that must be considered include:

• the type of pipe used.

• the friction characteristics of the pipe.

• the diameter of the pipe.

• the length of the pipe installed.

•the number and type of fittings used to connect the pipe at various locations in the system.

•the flow rate through the pipe.

System Types And Operation Pressure

Several different types of irrigation systems are available. The systems most commonly used are center pivot systems, cable tow systems, hose tow systems, solid set systems, and drip systems. In some areas of the country~ surface irrigation equipment is also use d.

Each of these systems has certain specific energy requirements. High-pressure irrigation equipment requires more horsepower to pump the same amount of water than medium- or low-pressure equipment. Before the low-pressure operation of any sprinkler system is selected, the application rate or rainfall under the system must be considered to prevent applying water faster than it can be absorbed by the soil.

Pumping Unit

The pumping unit is a critical factor in the design of an irrigation system. Many pumps will do the job of delivering water at the required volume and pressure; however, the pump should be selected based on its efficiency and the design requirements of your system, including expected operation time.

If the pump is properly selected, the most efficient operation will result. On the other hand, an improperly selected pump will likely be inefficient and can increase fuel costs.

Power Unit

The power unit is the element of the irrigation system that actually consumes the energy. There are several different types of units. Diesel and electric power units are most commonly used, but units that run on L.R. gas, propane, and other liquid petroleum gas (LPG) products are also available.

Selecting a power unit can be complicated. The initial price and hourly operation costs may not tell the whole financial story. Before making a final decision, thoroughly investigate the length of life of the power unit, maintenance costs, repair costs, electric demand charges, and labor requirements.

Volume Of Water

Finally, you must consider the total volume of water pumped when you evaluate the energy consumed by a system. For example, the energy consumed by an irrigation unit installed in an area where only 6 to 8 inches of supplementary water is needed in a growing season will be less than that consumed by a system in an area where 15 to 20 inches of water is pumped.

Evaluate each of the factors discussed here before choosing the final system components--only then can you select the most efficient system. For more information, consult your county Extension agent or refer to,these Extension circulars: ANR-546, "Energy And Irrigation: Elevation"; ANR-547, "Energy And Irrigation: Pipe And Fittings"; ANR-548, "Energy And Irrigation: The Pumping Unit"; and ANR-549, "Energy And Irrigation: The Power Unit."

| Publication No.

ANR-545 |

Date

March 1990 |

Larry M. Curtis, Extension Agricultural Engineer, Professor, Biosystems and Agricultural Engineering, Ted W. Tyson, Extension Agricultural Engineer, Associate Professor, Biosystems and Agricultural Engineering. |

Issued in furtherance of Cooperative Extension work in agriculture and home economics, Acts of May 8 and June 30, 1914, and other related acts, in cooperation with the U.S. Department of Agriculture. The Alabama Cooperative Extension System (Alabama A&M University and Auburn University) offers educational programs, materials, and equal opportunity employment to all people without regard to race, color, national origin, religion, sex, age, veteran status, or disability.

This document is author-produced (unedited).

Menu

Menu