- Home

- Managing An Irrigation System

- Planning System Hardware

- Farm Irrigation Systems & Cost Analysis

- Water Resource Development

- Micro Irrigation Handbook

- Related Links

Efficient Irrigation Planning

The Pumping Unit

Larry M. Curtis, Extension Agricultural Engineer

Ted W Tyson, Extension Agricultural Engineer

The flow rate and total head or pressure required in an irrigation system design must be determined before a pumping unit can be selected. The water requirement, or flow rate, of an irrigation system is usually referred to as the number of gallons per minute (gpm) that must be provided by the pumping unit to effectively irrigate an area. To determine the flow rate for your system, you must consider the number of acres in need of irrigation and the water needs of the crop you are producing.

The pressure requirement or total dynamic head (TDH) of an irrigation system is determined based on the elevation difference from the water source to the field to be irrigated, the pressure lost in the pipe and fittings used, and the pressure required by the system selected. The flow rate and TDH can then be used to choose the best pump to do the job.

Pump selection is one aspect of irrigation planning that is often overlooked or misunderstood. However, the right pump is very important to an energy-efficient installation. The horsepower required to continuously operate a pump can be calculated using the following formula:

HP = gallons per minute (gpm) x total dynamic head (ft.)

3,960 x pump efficiency

After the gpin and TDH for your system have been determined, the only variable remaining that can affect the horsepower requirement is the pump efficiency. If efficiency is low, the horsepower requirement will be higher; if efficiency is high, the horsepower requirement will be lower. An efficient pump requires less horsepower and therefore conserves fuel and energy. (See Figure 1.)

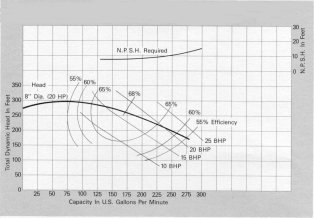

Pump manufacturers publish pump curves which indicate a variety of operating conditions for specific pumps, including the efficiency at various flow rates, pressures, and pump speeds (see Figure 2). It is important to remember, however, that a single pump has many different efficiencies. Before you select a pump, you should evaluate the pump's efficiency under the conditions of flow rate and pressure for your system.

If a pumping unit is to be operated under more than one set of conditions, select a pump that has a high efficiency throughout the range of operation. Also, it should be remembered that the horsepower calculated is the continuous horsepower that must be delivered to the shaft of the pump. Power losses that occur in auxiliary equipment and drive mechanisms or that are due to operation at high altitudes must be added to the power needed by the pump to determine the total horsepower requirement of the system.

When selecting a pump, you must also consider the suction characteristics of the pump. Different pumps have different suction-lift capabilities. The pump's suction capability can be determined from the pump curve describing its performance.

Situation: Flow Rate = 1,000 gpm TDH = 300 feet

Pump 2 the more efficient pump, can save you 2 gallons of diesel fuel per hour of operation. |

Figure 1. The Effect Of Pump Efficiency On Required Horsepower

For more information, consult.your county Extension agent or refer to the following Extension circulars: ANR-545, "Energy And Irrigatiorf'; ANR-546, "Energy And Irrigation: Elevation"; ANR-547, "Energy And Irrigation: Pipe And Fittings"; and ANR-549, "Energy And Irrigation: The Power Unit."

Figure 2. Sample Pump Rating Curve.

| Publication

ANR-548 |

Date

March, 1990 |

Larry M. Curtis, Extension Agricultural Engineer, Professor, Biosystems and Agricultural Engineering, and Ted W. Tyson, Extension Agricultural Engineer, Associate Professor, Biosystems and Agricultural Engineering. |

Issued in furtherance of Cooperative Extension work in agriculture and home economics, Acts of May 8 and June 30, 1914, and other related acts, in cooperation with the U.S. Department of Agriculture. The Alabama Cooperative Extension System (Alabama A&M University and Auburn University) offers educational programs, materials, and equal opportunity employment to all people without regard to race, color, national origin, religion, sex, age, veteran status, or disability.

This document is author-produced (unedited).

Menu

Menu