- Home

- Managing An Irrigation System

- Planning System Hardware

- Farm Irrigation Systems & Cost Analysis

- Water Resource Development

- Micro Irrigation Handbook

- Related Links

Efficient Irrigation Planning

The Power Unit

Larry M. Curtis, Extension Agricultural Engineer

Ted W Tyson, Extension Agricultural Engineer

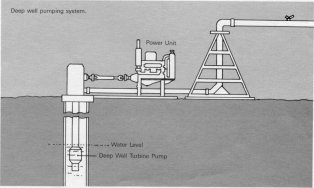

After an irrigation system, system components, and flow rate have been decided on, a pump must be selected that will develop the required discharge pressure while pumping the required gallons per minute. Next, a power unit must be selected that will produce enough power to operate this pump. Several types of power units are available. Diesel, propane, natural gas, or gasoline internal combustion engines are all used to drive pumps. Electric motors are also used for many pumping applications.

Horsepower Requirement

To choose the appropriate power unit, you must first determine the horsepower requirement of the pump-that is, the horsepower needed to run the pump continuously. This can be done by evaluating the pump curve that describes the pump you have selected. The horsepower can also be determined by using the following formula:

HP = gallons per minute x total dynamic head(ft.)

3,960 x pump efficiency

The calculated horsepower is the continuous horsepower that must be supplied to the pump.

Internal combustion engines are often rated for both continuous and intermittent horsepower. Caterpillar nactor Company describes intermittent and continuous horsepower as follows:

- INTERMITTENT-the horsepower and speed capability of the engine which can be utilized for about 1 hour, followed by an hour of operation at or below the continuous rating.

- CONTINUOUS-the horsepower and speed capability of the engine which can be used without interruption or load cycling.

Other engine manufacturers have similar definitions of continuous and intermittent ratings. Remember that, when selecting a power unit for an irrigation pump, the continuous horsepower is the rating that must be used.

An engine operating a pump is loaded for the duration of the pumping cycle, which may last for several days. The engine will operate under load continuously during this time. Also, keep in mind that accessory equipment, like generators, drive mechanisms, cooling systems, etc., will require additional horsepower. In addition, the horsepower capabilities of an engine decline as engines wear and at higher elevations. 'Ib detennine how much total horsepower your unit must supply, you must add the horsepower needed because of accessories, elevation, etc., to the horsepower required by the pump.

Engine Selection

Since engine selection is a critical aspect of system design, be sure that your dealer understands your need to select an engine that provides the required continuous horsepower without overload. Also, most suppliers of engines should provide engines with continuous ratings higher than the calculated rating to give some margin for wear and declining pump efficiency.

Before choosing a specific engine, determine the fuel consumption per hour from tables developed by the engine manufacturers. This is a good opportunity to.compare expected fuel consumption rates for different engines perforining the same job. This way, you can choose the one best suited to your needs and resources. Also, by knowing the fuel consumption rate per hour of operation and the gallons of water per minute supplied to the system, you can determine the fuel required to apply 1 inch of water per acre. Thus, you can calculate an estimate of annual operating costs per acre.

Electrical Power

Electric motors are often used to power irrigation systems. Where electrical power is available at a reasonable cost, this is a good way to power an irrigation pump. Low maintenance and ease of starting make electrical motors attractive. Unfortunately, large electric motors cannot be served by power suppliers in many rural locations. Check with your power company to determine if a large electric motor is practical for your farm.

Several charges are often associated with electrical power. Each of these should be determined before you decide to use electricity. A demand or horsepower charge is usually required. Also, charges for running lines to the pumping site may be assessed and pro-rated over a period of time. In addition, you will be charged for each kilowatt-hour of electricity used. These charges often run from 0.06 to 0.10 cents per kilowatt-hour. In some locations, power suppliers offer reduced kilowatt-hour charges for off-peak users. That is, if you agree to turn the motor off during ce~tain periods of the day as specified by the power supplier, you will be charged less for each kilowatt-hour.

Selecting the proper power unit for an irrigation pump is critical in an irrigation design. You must select a power unit.that has the horsepower needed to provide continuous duty service to the pump and accessories. Evaluate the energy consumption of the power unit you select. When the consumption is calculated, you can then determine the actual cost of applying 1 inch of water on 1 acre, and you can develop budgets for analyzing irrigation costs.

For more information, consult your county Extension agent or refer to the following Extension circulars: ANR-545, "Energy And Irrigation!; ANR-546, "Energy And Irrigation: Elevation"; ANR-547, "Energy And Irrigation: Pipe and Fittings"; and ANR-548, "Energy and Irrigation: The Pumping Unit "

| Publication No.

ANR-549 |

Date

March, 1990 |

Larry M. Curtis, Extension Agricultural Engineer, Professor, Biosystems and Agricultural Engineering, and Ted W. Tyson, Extension Agricultural Engineer, Associate Professor,Biosystems and Agricultural Engineering. |

Issued in furtherance of Cooperative Extension work in agriculture and home economics, Acts of May 8 and June 30, 1914, and other related acts, in cooperation with the U.S. Department of Agriculture. The Alabama Cooperative Extension System (Alabama A&M University and Auburn University) offers educational programs, materials, and equal opportunity employment to all people without regard to race, color, national origin, religion, sex, age, veteran status, or disability.

This document is author-produced (unedited).

Menu

Menu