- Home

- Managing An Irrigation System

- Planning System Hardware

- Farm Irrigation Systems & Cost Analysis

- Water Resource Development

- Micro Irrigation Handbook

- Related Links

Chemigation Procedures, Equipment And Safety

Ted W. Tyson, Extension Agricultural Engineer

Larry M. Curtis, Extension Agricultural Engineer

There are sound economic reasons for chemigation, or the injection of fertilizers or farm chemicals through an irrigation system. There are even better reasons to take the steps necessary to protect water sources from possible backflow of the chemical during the injection process. This hazard exists regardless of the type of water source (reservoir, stream, or groundwater) or the type of chernical (fertilizer, pesticide, or water treatment). This publication explains reasonable and available steps you can take to receive the econornic benefits of applying chemicals and plant nutrients through micro-irrigation systems, while at the same time protecting water resources.

Reasons to Chemigate

Chemigation is carried out for two basic purposes: either to apply chemicals (fertilizers, pesticides, etc.) to benefit the crop or soil; or to add chemicals (chlorine, acids, etc.) as a water treatment, usually to prevent or clear clogging problems. Water treatment is an essential part of system maintenance that assures reliable and uniform water delivery to the crop. Injecting fertilizers (fertigation) or pesticides provides other specific benefits:

- Uniform application of fertilizers or pesticides is much easier with a properly designed and operated micro-system than with conventional application methods.

- Fertilizer can be applied in small amounts throughout the season as the crop needs it. With conventional methods, large amounts are applied two or three times a season, increasing the chance that fertilizer will be washed away or carried below the plants' root zone by rains.

- Fertigation while irrigating frees the operator to do other things at the same time.

- Danger to the operator from chemicals can be reduced. Instead of several small tanks of chemical mix, only one or two large tanks are needed. The operator's contact with the chemicals is reduced, and the risk of accidents is reduced as well.

- The cost of chemigation, compared to that of aerial or ground application, is generally very competitive, particularly when two or more applications per year are made. Chemigation costs usually average from one-third to one-half the cost of other methods of application.

- Because the irrigation system is already in place, tractors and other equipment do not have to make repeated trips across the field. Chemigation thus saves money, time, and energy, while at the same time reducing soil compaction, which helps maintain a good environment for root growth.

Protection of the Water Source

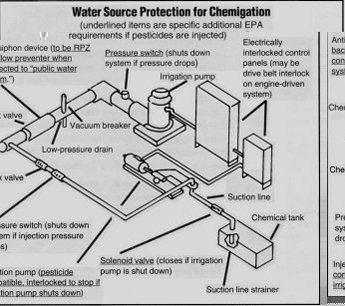

The most important water supply safety measure when injecting any chemical is backflow prevention. Basic backflow protection includes an anti-siphon check valve, an atmospheric vacuum breaker, and a low-pressure drain between the water source and the chemical injection point. The low-pressure drain should empty at least 20 feet from the well or water source.

Safety interlocks between the injection device and the irrigation system pump and a check valve in the injection line are also important to prevent the contamination of the water source. The safety interlocks shut off the injection pump when the irrigation pump stops. The check valve prevents backflow toward the injection pump.

For automatic operation, a pressure switch is necessary in the discharge line of the injection device. The pressure switch shuts off the irrigation pump if injection pressure drops or vanishes because of problems with the injection pump.

IMPORTANT: If the system is to be used to apply pesticides, EPA regulations call for the following additional or alternate requirements:

1.When the chemigation system is connected to a "public water system," a reduced-pressure zone backflow preventer (RPZ) must be used between the water source and the pesticide injection point instead of the anti-siphon device mentioned above. EPA defines a public water system as "...a system for provision to the public of piped water for human consumption if such system has at least 15 service connections or regularly serves an average of at least 25 individuals daily at least 60 days out of the year."

2. The pesticide injection pipeline must contain a normally closed, solenoid-operated valve on the intake side of the injection pump and connected to the system interlock to prevent fluid being withdrawn from the supply tank if the irrigation system shuts down for any reason.

3. The system must include interlocking controls to automatically shut off the system pump if water pressure drops below design levels. The injection pump must be interlocked to automatically stop if the irrigation pump stops.

4. Injection pumps or venturi injection devices must be made of materials compatible with pesticides and capable of being fitted with a system interlock.

State agencies and other agencies with regulatory authority may have additional requirements. The illustration shows a typical system with both basic safety equipment and EPA-required devices for pesticide application.

The EPA also requires labeling of all pesticides approved for application through irrigation systems. Labels on any pesticide that is not intended to be applied through chemigation will state: Do not apply this product through any type of irrigation system. Labels on pesticides that are intended to be applied by chemigation will list the types of irrigation systems intended to be used. Apply only those pesticides labeled for use in an irrigation system. Labels also have information on approved procedures and other restrictions.

Injection Point Location

The injection point must be between the anti-siphon device and the system filters. To give time for the fertilizer or chemical solution to mix uniformly in the irrigation water, the fine between the injection point and the filter station should include at least 25 feet of pipe and two 90-degree turns. This arrangement creates flow turbulence and allows any chemical precipitation to form in time for the filter to catch it, preventing it from clogging the system.

Types of Injection Pumps

Several types of injection pumps are available. Positive displacement pumps can inject chemicals precisely and are operated by electricity, internal combustion engines, or water engines. The other basic type of injection device operates on the principle of pressure differentials, rather than positive displacement.

Electrical or engine-powered pumps are usually the piston or diaphragm type. Generally, diaphragm pumps have less bearing surface exposed to the injected material and as a result have less wear and may last longer than a piston pump. Diaphragm pumps are also adjustable during operation, while piston pumps are not. For this reason, diaphragm pumps are becoming more popular.

Water-powered proportional pumps are also becoming more popular. Some can be adjusted during operation and some cannot. Their real advantage is that they do not need any outside power source to operate. This feature can become a disadvantage, however, on high-flow systems when the irrigation system operating pressure must be increased to provide water power to drive this type of pump.

Venturi suction devices are simple and inexpensive, operating by a pressure difference (generally 20 percent) from one side of the venturi to the other. The injection rate depends on this pressure drop. In systems with large irrigation flow rates, energy costs may prevent installation of the venturi in the main line. In this case, a venturi can be installed in series with a small centrifugal pump parallel to the main line. Even with the centrifugal pump, the pressure-dependent venturi may not provide the accuracy necessary for pesticide injection without additional pressure regulation measures.

Differential pressure tanks or batch tanks are recommended for fertilizer injection only. Even then, they may not be entirely satisfactory. They have their inlet and outlet connected to the main line at two points having different water pressures. The pressure difference causes the water to flow through the tank and displace the fertilizer it contains. Although no power is necessary, the concentration of the fertilizer varies a great deal. When using batch injection, all of a batch should be emptied in each valve zone of the irrigation system to maintain distribution uniformity.

Injection Pump Sizing

Injection pumps are sized based on their injection flow nate in gallons per hour (gph). As mentioned above, flow rates of some types of pumps are adjustable within a certain range. In all chemigation procedures, the three basic factors to be taken into account are:

1. Injection rate (injection pump capacity, in gph);

2. Amount of material to be injected (gal--usually an active ingredient, which may be measured in pounds, diluted in more or less water); and

3. Time available for injection.

Amounts injected vary a great deal. Amounts of fertilizers injected are usually so much larger than amounts of materials used for water treatment or pesticide application that a higher capacity pump is needed. Thus two pumps will be needed (two injection rate capacities) if both types of chemigation are done.

Chemigation Procedures

The basic chemigation formula relates the three factors mentioned above:

Injection rate (gal/hr) =Amount to be injected (gal)

Injection period (hr)

In the case of fertilizers and pesticides, the amount is determined by the per acre application rate and the number of acres in the irrigation zone. The amount of active ingredient needed is mixed in the injection tank with enough water so that at the given injection rate (may be adjustable) the total amount of the chemical solution will be applied within the recommended injection time. If dry materials are used, it is important that enough water be added to completely dissolve the dry materials. Also, the system must be thoroughly flushed after injection.

In the case of water treatment, for example chlorination, the same basic formula is used, but the purpose is to achieve a recommended concentration (percentage or parts per million) of the chlorine in the water going through the system, rather than to apply a certain amount of material to the crop. To do this, the system flow rate must be known. In this case, not only the amount of active ingredient, but the injection rate of the chlorine must be calculated against the system flow rate to achieve the desired concentration.

For detailed information on specific chemigation procedures, such as fertigation and chlorination, see publications on these topics in this handbook.

Chernigation Calibration

For most chemigation procedures, three factors must be accurately determined:

1. System flow rate,

2. Injection pump flow rate, and

3. System pass-through time.

System design specifications and manufacturers' ratings are not adequate for chemigation purposes.

System Flow Rate. The simplest and most accurate method of determing the system flow rate is to install a system flow meter. Propeller flow meters are highly recommended. These measure instantaneous system flow (gpm) and record total flow amounts. Pitot or bobbin type flow meters are less expensive and may be sufficient. These meters measure only instantaneous flow. Proper meter installation is critical to accurate readings. For best results, allow 6 to 10 diameters of straight pipe on either side of the meter. For example, if 4-inch pipe is used, the meter should be placed in the center of a straight, unobstructed section of pipe 48 to 80 inches long.

System flow rate information is especially needed for water treatment procedures. in addition, a system flow meter (especially a propeller-type meter) is useful for monitonng system performance for maintenance purposes.

Injection Pump Flow Rate. In all chemigation procedures, there will be a desired injection rate, to apply the needed amount of material in the desired time period. Injection rate is checked by actual measurement. It is important that the actual materials be used (active ingredient + dilution water, if any) and that the injection pump be discharging into the operating irrigation system. You want to know how many gallons of the actual materials the pump will inject per hour while overcoming system pressure.

With the system operating at normal pressure and flow rate, find out the injection rate by injecting a measured, known amount of the material to be applied, and checking the time needed to pump this amount. For example, if the pump injects one-half gallon in 5 minutes, it is delivering 6 gallons per hour.

The reason for using actual materials in the test is that different materials (fertilizer, chlorine, etc.) are likely to have different viscosities, so the same pump may have different injection rates for the different materials at the same pump setting. Further, the same material in different solution strengths (active ingredient plus dilution water) may have dfferent viscosities and therefore different injection rates. Water injection is not an accurate calibration method.

The proper procedure is to make up a test stock solution of the material in the same proportions (active ingredient + water) you expect will be used in the chemigation process itself. if the actual injection rate turns out to be different from the desired rate, choose one of the following options:

1. Adjust injection pump setting up or down, if it is adjustable, then retest to confirm. Repeat if necessary.

2. Increase or decrease the injection period (time over which injection occurs) to match determined actual injection rate, if this results in a new injection period within acceptable limits.

3. Adjust solution strength to match determined injection rate, then retest with a new test stock solution, repeating the calibration procedure until the combination of actual injection rate, injection period, and solution strength (or amount of active ingredient applied) is satisfactory.

Injection Rate Calibration Tip A measuring container called a "graduated cylinder" is very useful in checking injection rate for injection pumps delivering up to fifteen gallons per hour. A graduated cylinder that holds 1,000 milliliters (about 1 quart 2 ounces) is most convenient. Draw injection solution directly from the cylinder, using a watch with a second hand to see how much is injected in one minute. This gives you the injection rate in milliliters per minute (ml/min). To convert to gallons per hour, the formula is: gal/hr = ml/min ÷ 63.1 For example, if your pump is injecting 760 ml/min, this rate is 12 gal/hr: 760 ÷ 63.1 = 12.04 |

System Pass-through Time. Pass-through time is the time water takes to flow from the system pump to the farthest emitter in the irrigation zone under normal operating conditions. This is not simply the time it takes for water to first appear at the emitter after the system is turned on, since system pressure and flow rate will not have stabilized at normal operating levels.

The only way to accurately determine pass-through time is to inject a chemical, such as a dye, into the normally operating system at the injection pump and check the elapsed time until it appears at the emitter farthest from the injection station. A dye called "fluorescein" is available from irrigation suppliers. Another method is to inject chlorine and use a D.P.D. chlorine test kit to check for the presence of chlorine at the farthest emitter (see Circular ANR-651, Chlorination). In making this check, use the test kit chemical for total chlorine, not the chemical normally used for chlorination testing, which checks for free chlorine. Once system pass through time is established, it should not have to be checked again unless alterations are made to the system.

References

Boswell, Michael J. 1990. Micro-Irrigation Design Manual. James Hardie Irrigation. El Cajon, California.

Curtis, Larry M. 1982. Chemigation: Chemical Application Through Irrigation Equipment. SW82-2. Alabama Cooperative Extension Service, Auburn University.

Pitts, Donald J., and Phil L. Tacker. 1987. Trickle Irrigation: Causes and Prevention of Emitter Plugging. MP 271. Arkansas Cooperative Extension Service, University of Arkansas.

Tinsworth, Edward F. 1987. PR Notice 87-1. Label Improvement Program For Pesticides Applied Through Irrigation Systems (Chemigation). Registration Division (TS-767C), Environmental Protection Agency, Washington, D.C.

| Publications included in the Alabama Micro-Irrigation Handbook present up-to-date information on practical irrigation methods that save energy and water while protecting water quality. For more information, see your county Extension agent. |

Publication No.

Micro-Irrigation Handbook ANR-650 |

November 1998 |

Ted W. Tyson, Extension Agricultural Engineer, Associate Professor, Biosystems and Agricultural Engineering, Larry M. Curtis, Extension Agricultural Engineering, Professor, Biosystems and Agricultural Engineering. |

Issued in furtherance of Cooperative Extension work in agriculture and home economics, Acts of May 8 and June 30, 1914, and other related acts, in cooperation with the U.S. Department of Agriculture. The Alabama Cooperative Extension System (Alabama A&M University and Auburn University) offers educational programs, materials, and equal opportunity employment to all people without regard to race, color, national origin, religion, sex, age, veteran status, or disability.

This document is author-produced (unedited).

Menu

Menu