- Home

- Managing An Irrigation System

- Planning System Hardware

- Farm Irrigation Systems & Cost Analysis

- Water Resource Development

- Micro Irrigation Handbook

- Related Links

Acid Injection for System Maitenance

Larry M. Curtis, Extension Agricultural Engineer

Ted W. Tyson, Extension Agricultural Engineer

The two most common causes of clogging in micro-irrigation systems (assuming adequate filtration) are growth of algae or bacteria and build-up of mineral deposits in the lines or emitters. Growth of algae and bacteria is so common that chlorination to prevent this kind of clogging is recommended as a regular maintenance procedure. See Circular ANR-651, Chlorination to Prevent Clogging, in this handbook. Clogging by mineral deposits is less frequent, but can be a problem. The usual treatment is injection of acids on an as-needed basis, most often using sulfuric, hydrochloric (muriatic), or phosphoric acids. While acids can also destroy or slow the growth of some algae and bacteria, acid injection is not recommended for treatment of biological clogging problems.

| CAUTION: injection of acids requires special equipment and can be hazardous to workers, irrigation water supplies and crops. This publication explains the basics of acid injection, including equipment and safety procedures. However, for the above reasons, if you are considering acid injection you should also seek expert assistance. For further information, consult your county Extension agent. |

Safety

The first safety principle in handling acids is: NEVER ADD WATER TO ACID; ALWAYS ADD ACID TO WATER. If water is poured into acid, the acid will splatter, often violently. Other safety requirements are:

- All workers must be thoroughly trained to handle acids safely and everyone in the vicinity of the injection system should wear protective clothing. Also, workers must be specifically warned not to drink or wash with irrigation system water.

- All injection system components must be acid-resistant, since corrosion-caused failure is likely to result in spraying of acid solution onto anyone standing nearby. Injection equipment should be shielded in such a way as to prevent acid sprays if leaks do occur.

- Since accident prevention cannot be foolproof, the site should be made accident-ready, with an emergency shower installed (taking water upstream of the acid injection point) and first-aid supplies available (including eyewashes).

Equipment Requirements

All injection system components must be acid-resistant. This includes acid storage and supply tanks, the injection pump, and all valves, lines and other equipment, and usually means that these components are either made of or lined with plastic, polyvinyl chloride or polyethylene. You will also need an accurate pH test kit and containers for accurately measuring and dispensing liquids in liter and milliliter amounts. For more information on injection equipment and procedures, see Circular ANR-650, Chemigation Procedures, Equipment and Safety, in this handbook.

Reasons for Acid Injection

Acid injection is most often done to dissolve mineral deposits which cause clogging. iron precipitation causes a reddish stain in the water and red-colored deposits. Other mineral deposits (usually calcium or magnesium) are usually whitish. Bacterial and algal masses, on the other hand, are almost always dark-colored. A laboratory water analysis will indicate whether your irrigation water has the potential for mineral clogging problems. See Circular ANR-649, Water Quality, in this handbook. You should also monitor the system regularly, opening the ends of lateral fines for visual inspection and checking emitters and filters for possible problems. Circular ANR-648, Evaluating Water Distribution Uniformity, explains a sampling procedure you can use to deter mine whether dogging has become a significant problem.

Treatment consists of injecting acid to bring system water pH to between 2.0 and 4.0, depending on the severity of the problem. If mineral deposits are allowed to build up to the point that emitters become totally clogged, they will probably have to be replaced. Commercially available acids include sulfuric, hydrochloric (muriatic), and phosphoric acids.

Where irrigation water pH is consistently high, acid injection may be used as an aid to chlorination treatment. Lowering the water pH enhances the chlorine's biocidal action and can prevent precipitation of minerals (especially iron) that might otherwise result from chlorination. For this purpose, reducing pH to 6.5 is usually sufficient. Note that the acid injection/chlorination practice requires two injection systems, since the acid must be injected separately upstream of the chlorine injection point.

NOTE: Where high-pH irrigation water is used for acid-loving crops, such as blueberries, acids may be injected continuously during every irrigation cycle as a means of preventing this water from eventually raising soil pH to an undesirable level for the crop grown. This practice, though similar to that described here, is not covered in this publication since it is rarely needed in Alabama and also involves special cost, safety and equipment considerations.

Acid Injection Procedure

The following steps explain procedures for injecting acids as a treatment for mineral deposits. The purpose is to fill the irrigation lines (one zone at a time) with water acidified to the proper pH, let the system sit for 24 hours, then flush. (Procedures for injecting acid as an aid to chlorination. are similar, with the desired pH, amounts and times adjusted to fit the requirements of chlorination.)

Step 1. Test a sample of your irrigation water to determine how much acid is needed to reduce pH to the desired level. This process is called "titration" and is the only way to know how much acid to use. The reason for this is that water samples from different sources may have the same pH but different chemical compositions. The-change in pH that results from adding acid depends on the precise chemical composition of the water, and not just on the original pH reading. Thus a given amount of acid may result in different pH changes in two water samples that have the same starting pH measurement.

To perform the test, place 10 liters of irrigation water in a suitable container and measure its pH. Then add acid a half-milliliter at a time. At each step, stir the batch thoroughly after adding acid, then measure the new pH of the water sample. Make a chart similar to the following:

ML ACID ADDED |

NEW pH |

0.5 |

__ |

1.0 |

__ |

1.5 |

__ |

2.0 |

__ |

2.5 |

__ |

3.0 |

__ |

etc. |

etc. |

When the pH of the water sample reaches the desired level, you know the proportion of acid that will be needed to treat any given amount of irrigation water. For example, if 3.0 milliliters of acid were needed, the proportion is 3 parts in ten thousand, or 0.0003 (one milliliter is one-thousandth of a liter, and the sample is 10 liters). This figure, called the ACID FACTOR, is used in the following steps.

Step 2. You will inject acid for approximately one hour. Use the formula below to determine how much acid to inject, depending on your system's flow rate in gallons per hour. For example, if your system pumps 90 gpm, the amount pumped per hour is 90 gal/min X 60 min/hr= 5400 gallons/hour.

Acid Factor x gallons/hr = gallons acid to inject/hr

Example:

0.0003 Acid Factor x 5400 gal/hr = 1.62 gallons acid to inject/hr

Step 3. Fill the injection supply tank with enough water so that when you add the acid the injection pumping time for this amount will be one hour. IMPORTANT: The injection pump flow rate for the acid solution is not necessarily the same as the flow rate pumping water only or pumping other chemicals. See ANR-650 in this handbook for calibration procedures.

Example: If the injection pump flow rate will be 12 gallons per hour and 1.62 gallons of acid are to be used, amount of water to place in injection supply tank is 12-1.62=10.38 gallons.

CAUTION: Add acid only after placing water in the injection supply tank.

Step 4. Start the system pump. When the system has reached normal operating pressure and flow rate, start acid injection. Allowing enough time for acidified water to reach sampling points, check water pH first after the filters, then at an emitter. If the pH is at the desired level, continue injection without change. If the pH is not at the desired level, you will have to adjust the acid injection rate either by changing the acid/water proportion in the injection supply tank or by adjusting the injection pump setting if possible.

Step 5. Continue injection for approximately one hour, shutting down the system just before the injection tank is emptied. This is to leave the lines as far as possible filled with the acidified water. Dispose of any remaining acid/ water solution safely. After 24 hours, restart the system and flush thoroughly, one lateral at a time. Repeat procedure if needed.

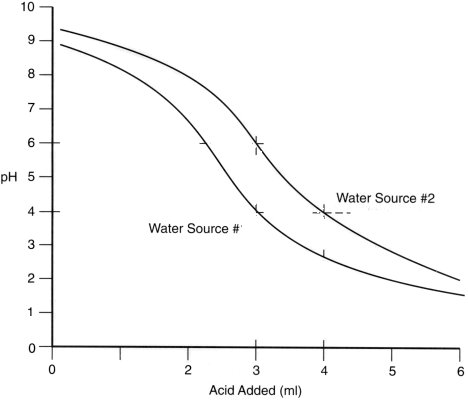

Example Titration Curves for Different Water Sources

Before acid is added, both water samples test at a pH near 9. Adding 3 ml acid to sample #1 brings its pH to 4, while the same acid amount brings sample #2 only to pH 6. It takes 4 ml of acid to bring sample #2 to pH 4.

Adapted from M. J. Boswell Micro-Irrigation Desigh Manual, James Hardie Irrigation Co., El Cajon, CA

Be Safe: Always Add Acid To The Water Never Pour Water Into Acid. |

References

Boswell, M.J. 1990. Micro-Irrigation Design Manual. James Hardie Irrigation Co., El Cajon CA.

Kovach, Steven P. 1992. Unpublished data.

Meyer, J.L. 1985. Cleaning drip irrigation systems. ASAE Pub 10-85, Drip/Trickle Irrigation in Action, pp. 41-44. American Society of Agricultural Engineers, St. Joseph Mi.

Zazueta, F.S. and A.G. Smajstrla. No date. Injection rate estimations to neutralize excess bicarbonates in irrigation water. Water Management Utilities, 3.3.1-3.3.6. IFAS, University of Florida.

Publication No. Micro-Irrigation Handbook ANR-652 |

DEC. 1998 |

Larry M. Curtis, Extension Agricultural Engineer, Professor, Biosystems and Agricultural Engineering, and Ted W. Tyson, Extension Agricultural Engineer, Associate Professor, Biosystems and Agricultural Engineering. |

Issued in furtherance of Cooperative Extension work in agriculture and home economics, Acts of May 8 and June 30, 1914, and other related acts, in cooperation with the U.S. Department of Agriculture. The Alabama Cooperative Extension System (Alabama A&M University and Auburn University) offers educational programs, materials, and equal opportunity employment to all people without regard to race, color, national origin, religion, sex, age, veteran status, or disability.

This document is author-produced (unedited).

Menu

Menu