- Home

- Managing An Irrigation System

- Planning System Hardware

- Farm Irrigation Systems & Cost Analysis

- Water Resource Development

- Micro Irrigation Handbook

- Related Links

Applying Fertilizers Through the System

Steven P. Kovach, Extension Horticulturist

Larry M. Curtis, Extension Agricultural Engineer

Ted W. Tyson, Extension Agricultural Engineer

James E. Hairston, Extension Water Quality Scientist

One of the advantages of a micro-irrigation system is that fertilizers can be applied through the system while the crop 3. The system must be given time to reach normal is being irrigated. This process is called "fertigation." The main benefits of fertigation capability are:

- Energy savings through reduced field operations

- Labor savings in fertilizer application

- Improved efficiency of fertilizer use by crop

- Flexible control over timing of fertilization

Fertilizers applied through the micro- system are more efficiently used by plants because only a small amount is maintained in the soil at a time; thus leaching and run-off from rainfall are minimized throughout the growing season. Applied in proper amounts, injected fertilizers also are less likely than soil-applied dry fertilizers to injure the plant's root system from salt damage, since the liquid fertilizer is highly diluted in the irrigation water. Fertigation provides another significant benefit in making fertilizer application possible at any time, regardless of the crop's growth stage or the field's accessibility to machinery.

While fertigation of tree crops is possible, research findings to support recommendations are not currently available. Fertigation is practiced most extensively in Alabama on vegetable crops (including strawberries) grown in rows or beds. Therefore this publication focuses primarily on these crops. Growers wishing to fertigate tree crops should proceed with caution. Nitrogen and potassium fertilizer materials are best suited for application through the irrigation system. Phosphorus injection is not recommended since it is more likely to cause unwanted chemical reactions in the irrigation water. Also, pre-plant phosphorus application is usually sufficient for most crops.

Key Points to Remember

1. Fertilizers must not be injected in combination with pesticides or chlorine.

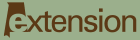

2.The injection point must be upstream of the filters.

3. The system must be given time to reach normal operating pressure and be fully charged before injecting fertilizers.

System Considerations

Two important system design factors are backflow prevention and choice and sizing of the injection pump:

- Backflow prevention devices must be installed in both the main system line and injection pump line to prevent accidental backflow of fertilizers into the water source.If backflow prevention devices are not installed, contamination of the water source is very likely if power is lost or the system breaks down during fertigation.

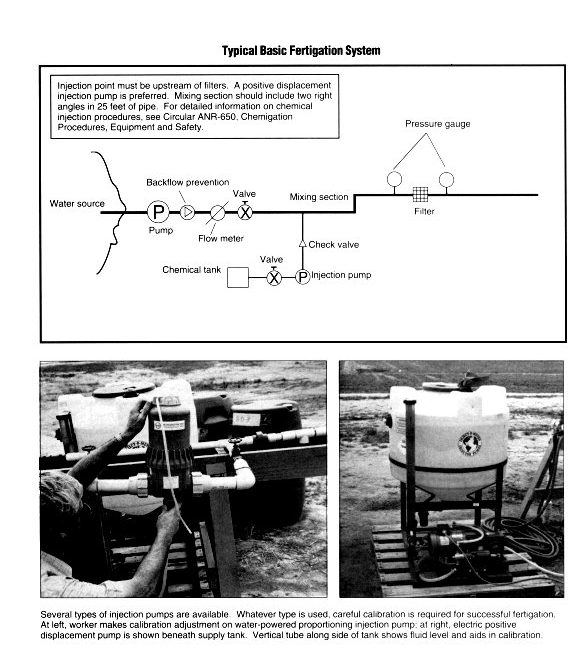

- Positive displacement injection pumps give better control of injection rates and are preferable to venturi or pressure differential devices. The injection pump should be sized so that the maximum fertilizer apphcation to be scheduled at any one time during the season can be completed in not more than 90 minutes.

The illustration shows a typical fertigation system. For information on necessary equipment, calibration, etc., see Circular ANR-650, Chemigation Procedures, Equipment and Safety in this handbook. Also, your County Extension Agent can help you get more information on fertigation equipment and design requirements.

Fertigation Scheduling

In most situations, a portion of the needed fertilizer is best applied pre-plant, and the remainder injected through the micro-system during the season. Dry fertilizers containing phosphorus (P) are difficult to apply through the micro-system without clogging problems. For typical crops, all of the phosphorus and micronutrients needed by the crop should be broadcast and incorporated before planting, as well as 30-40% of the nitrogen (N) and potassium (K). If fertilizer is banded in beds, the band must be within the wetting pattern of the emitters. Fertilization rates should be based on soil test recommendations for the crop to be grown. When requesting soil tests, be sure to specify that the crop will be micro-irrigated.

Pre-mixed commercial nitrogen and potassium liquid fertilizers are easier to use and less likely to cause clogging than are dry fertilizers. However, liquid-form fertilizers are usually more expensive and may be in limited supply. Whether liquid or dry materials are used, the procedure is first to determine the total amounts of fertilizers to be injected during the season, then to develop a schedule of amounts to be injected.

Fertigation schedules usually divide the portion of the total recommended fertilization rate to be injected into varying amounts or percentages for each week of the growing season, depending on the growth stage of the particular crop. Schedules for most crops call for injecting smaller amounts in the early weeks and larger amounts at mid-season, then tapering off in the last few weeks. Recommended fertigation schedules for various crops are given in publications on these crops included in this manual. Your County Extension Agent can help you get more information on fertigation scheduling.

Although fertigation schedules are formulated on a weekly basis, daily applications (or six days per week) are normally best for most vegetable crops. Daily fertigation ensures better uniformity of application and reduces risk of emitter clogging and salt damage to the crop. For crops not grown under plastic mulch, applying small amounts frequently also eliminates risk of losing large amounts of fertilizer by leaching during a heavy rain.

Calculating Fertigation Injection Amounts

Simple arithmetic can be used to calculate amounts of fertilizer materials to inject. The steps are slightly different for dry and liquid materials, but in both cases the purpose is to figure amounts of as-purchased fertilizer materials to apply, based on the recommended fertilizer rate per acre, percent to be applied per application, number of acres irrigated (the zone size), and percent analysis of the materials.

FOR DRY FERTILIZER MATERIALS, the formula to use is:

lbs dry fertilizer/application = lbs act./acre/season X % to apply/week X acres irrigated

-

% analysis of fertilizer X applications/week

% to apply per week: 8%

Acres irrigated (zone size): 5 acres

% analysis of fertilizer: (33.5-0-0) ammonium

nitrate Applications per week: 6

lbs dry fertilizer/application = 125 lbs act./acre. X.08/week X 5 acres = 24.87 lbs ammonium nitrate

.335 X 6 applications/week

FOR LIQUID FERTILIZER MATERIALS, the formula uses the pounds per gallon of the premixed solution and gives the gallons of as-purchased fertilizer needed per application. Your supplier should be able to tell you liquid fertilizer weights per gallon, if this information is not on the label. The Formula is:

gallons fert/application = lbs act./acre/season X % to apply/week X acres irrigated

% analysis of fert X lbs/gal of solution X applications/week

EXAMPLE: With the same fertilizer recommendation and situation as in the above example, but using a premixed 7% N solution weighing 10.5 lbs/gal, you would need:

gallons fert/applic. = 125 lbs act./acre/season X .08/week X 5 acres = 11.34 gal

07 X 10.5 lbs/nal X 6 annlic/week

Determining Injection Period

Injection of fertilizers for vegetables usually should be done over a period of at least 60 minutes, but not more than 90 minutes. If fertilizers are simply dumped into the system in a quick slug dose, clogging is more likely and the fertilizer materials are not as likely to be spread uniformly over the irrigation zone. On the other hand, if fertigation takes more than 90 minutes, there may be potential at times for over-watering and leaching of fertilizers out of the root zone, particularly in sandy soils.

It is important to realize that injection time should have no effect on total actual fertilizer applied per application. It should only affect the dilution strength of the injected solution. That is, you simply add water to make up an amount that your injection pump will put into the system in the desired time.

Fertilizer injection pump capacities typically range from 15 to 60 gallons per hour. Injection rates for some types can be adjusted over a certain range. If you want a fertigation injection period of 60 minutes and you have a 30-gph injection pump, you will need 30 gallons of fertilizer solution. For a 90-minute injection time, you will need 45 gallons (1.5 hrs x 30 gal/hr).

For dry fertilizer materials, fill the injection supply tank with on half the water needed, then add fertilizer slowly, with constant agitation. Do not add fertilizer so fast that the material begins to settle to the bottom. Then add the rest of the water needed. CAUTION: The dry fertilizer material must be capable of being completely dissolved in the quantity on water used. See discussion of solubility below.

For liquid fertilizer materials, the as-purchased fertilizer is a quantity of liquid, and you may be able to inject the fertilizer directly from the container, without adding any water (especially if your injection pump rate is adjustable). In the example above, the amount to be injected is 11.34 gallons. If the injection pump rate is 30 gph and you want a 60-minute injection period, you will add 18.66 gallons of water to get the 30 gallons needed (11.34 + 18.66= 30). For a 90-minute injeciton period, simply add 15 more gallons to total 45 gallons (again with a 30-gph injection pump).

Making Needed Adjustments

The above examples involve only one fertilizer element, nitrogen, in order to simplify the explanation. When nitrogen and potassium are injected together, as is often done, the principles of the procedure and the calculations are similar. A practical difficulty sometimes arises when a pre-mixed N and K formulation is desired to be used and the proportions do not match the recommeded fertilization rate. For example, it the fertilization rate recommended ts 10 pounds N and 240 pounds K2O per acre, the pre-plant application amounts will have to be adjusted if the fertilizer available for injection has an 8-0-8 analysis. The solution in this case might be to apply pre-plant 60 pounds K2O (from a single-element source) and none of the nitrogen. This would leave equal amounts of N and K2O to be injected, which matches the 8-0-8 fertilizer analysis.

| Important: The system must be turned on and allowed to reach normal operating pressure and be fully charged before injection is started. If fertigation is not being done on a daily basis, the system must be kept on after injection is finished and allowed to run long enough to flush all fertilizer materials from the lines. |

Choosing Dry Fertilizer Materials

The most important factors in choosing dry fertilizer materials for micro-system injection are:

- Solubility (easy to dissolve in water)

- Low risk of chemical reactions with water impurities

- Avoidence of unwanted effects on soil pH

Because of the likelihood of unwanted chemical reactions, phosphorus (P) should not be injected in micro- systems. If micro-nutrients are injected, chelated forms, rather than sulfates, should be used.

Some feritlizer materials have the effect of either raising or lowering pH. Since the fertilizer will be delivered to a relatively small area, the effect on soil pH can be significant. Fertilizer materials should be chosen with this in mind and coordinatied with other soil and crop management practices to maintain optimum soil pH.

The table shows at a glance the kinds and forms of nitrogen and potassium sourced best adapted to micro- injection, their solubility and pH-effects, and cautions that should be observed.

Avoiding Solubility Problems

Solubility is critical when using dry fertilizers. Any dry feritlizer elements used must always be thoroughly mixed and dissolved before injection. Check the solubility figures in the table to make sure the feritlizer you intend to use will dissolve completely. For example, the table shows that 9.8 pounds of ammonium nitrate will dissolve in one gallon of water, a ratio of almost 10 to 1 (lb/gal). In a typical situation, for example injecting 25 pounds of ammonium nitrate using 30 gallons of water, the fertilizer material/water ratio is only .8 to 1, and the ammonium nitrate can be easily dissolved.

Using potassium nitrate (13-0-44) as the N source, however, would not be possible at the same dilution. Only 33 pounds can be dissolved in 30 gallons of water (solubility 1.1 lbs/gal), whereas 64 pounds of potassium nitrate would be needed:

125 lbs act./acre/season X .08/week X 5 acres = 64.1 lbs potassium nitrate

.13 X 6 applications/week

If you intend to combine two or more dry fertilizers, you should test solubility of the combination in a gallon to water. The procedure is to take measured amounts of the fertilizers in the ratio they will be used, basing the amounts on the solubility figures given in the table. First add and mix the measured amount of the fertilizer with the lowest solubility, then slowly add (while mixing) the other fertilizer(s).

Characteristics of Dry Fertilizer Materials

Fertilizer element |

Best forms |

Solubility (lbs/gal of cold water) |

Effect on pH |

Cautions/Comments |

Nitrogen |

Ammonium nitrate Potassium nitrate Calcium nitrate |

9.8 .lbs/gal 1.1 lbs/gal 8.5 lbs/gal |

Lowers Raises Raises |

Avoid: Anhydrous ammonia, aqua ammonia, ammonium phosphate

Cautions: 1. Calcium nitrate will cause clogging unless water is low in bicarbonates 2. Monitor pH: some N sources will raise the water pH, increasing clogging potential |

Potassium |

Potassium sulfate Potassium chloride Potassium nitrate |

0.6 lbs/gal 2.3 lbs/gal 1.1 lbs/gal |

Neutral Neutral Raises |

Potassium nitrate often used for combined N and K; has relatively low solubility |

References

Branson, R. L. et al. 1981. Application of chemicals through drip systems, in Drip Irrigation Management, Leaflet 21259, Division of Agricultural Sciences, University of California.

Hochmuth, G. J. and G. A. Clark. 1991. Fertilizer Application and Management for Micro (or Drip) Irrigated Vegetables in Florida. SS-VEC-45, Florida Cooperative Extension Service, University of Florida.

Hochmuth, G.J. 1992. Feritlizer management for drip-irrigated vegetables in Florida, HortTechnology 2(1) Jan/Mar 1992, 27-32.

Kovach, S. P. 1984. Injection of Fertilizers into Drip Irrigation Systems for Vegetables. Circular 606, Florida Cooperative Extension Service, University of Florida.

Lacascio, S.J. et al. 1992. Water and Nutrient Requirements for Drip-Irrigated Vegetables in Humid Regions. Southern Cooperative Series Bulletin 363, Agricultural Experiment Station, IFAS, University of Florida.

Lorenz, O. A. and D.N. Maynard. 1988. Handbook for Vegetable Growers, 3rd ed. New York: John Wiley and Sons.

Sanders, D. C. 1989. Drip Fertigation Systems. Leaflet 33-D, N.C. Agricultural Extension Service, North Carolina State University.

Sneed, R. E. No date. Trickle Irrigation. North Carolina Agricultural Extension Service, North Carolina State University.

Publication No.

Micro-Irrigation Handbook ANR_ 653 |

Jan. 1999 |

Larry M. Curtis, Extension Agricultural Engineer, Professor, Biosystems and Agricultural Engineering, Ted W. Tyson, Extension Agricultural Engineer, Associate Professor, Biosystems and Agricultural Engineering, Steven P. Kovach, Extension Horticulturist, and James E. Hairston, Extension Water Quality Scientist. |

Issued in furtherance of Cooperative Extension work in agriculture and home economics, Acts of May 8 and June 30, 1914, and other related acts, in cooperation with the U.S. Department of Agriculture. The Alabama Cooperative Extension System (Alabama A&M University and Auburn University) offers educational programs, materials, and equal opportunity employment to all people without regard to race, color, national origin, religion, sex, age, veteran status, or disability.

This document is author-produced (unedited).

Menu

Menu