Installation

Do yourself a favor and have a look at the orientation of the dizzy, rotor,

and the No 1 plug wire on a running vehicle before installation. What you

see here is wrong. I had never worked on one of these type distributors

before and made a wrong guess. I looked at a 1989 Chevy Truck to get the

correct orientation. It was stickered for 0d base timing. I found out later

that my engine likes 6d, as described in Bruce's Tuning Tips. By using

6d base timing it will still run while in "limp home" mode--like when a

sensor goes bad.

You may also recognize the yellow Accel SuperCoil as being the point

type coil. I've since replaced it with an OEM style coil to narrow my list

of unknown variables during a troubleshooting session, but that wasn't

the problem. I think either will work.

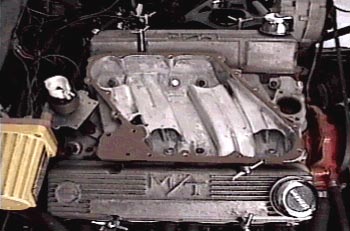

The plenum gasket was not available. I made mine by laying the gasket

material on the manifold plenum and carefully tapping around the edges

with a hammer. The sharp edges of the manifold cut the gasket. A leather

hole punch was used to cut out the bolt holes. It's an old mechanic's trick

and works well.

The brown area of exposed gasket in the lower left is where the EGR

valve would bolt on. I fashioned a plate of steel to block this off after

the photo was taken.

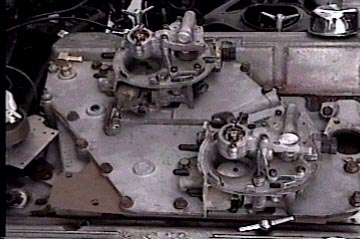

With the gasket in place, the plenum cover and TBIs were installed.

Notice the mechanical linkage between the units and how each throttle body

contains a single injector. Only the rear TBI has a TPS, but both have

an IAC. The front TBI has a fuel accumulator assembly where the rear TBI

has a fuel pressure regulator. As designed by GM the fuel would be fed

to the front unit and then what is normally the return would direct fuel

to the inlet of the rear unit (in-series fuel flow arrangement).

With that configuration the front and rear units saw different pressures

and therefore the injectors were calibrated differently and were not to

be interchanged.

I eliminated the stock fuel pressure regulator and the in-series fuel

flow arrangement and used an aftermarket adjustable fuel pressure regulator

by Mallory. Fuel is routed from the fuel pump to each TBI and then thru

the pressure regulator to the return line. This provides constant and equal

fuel pressure to each TBI. The injectors were replaced by 55lb/hr units

from a '91 Chevy PU with a 350 engine. Once again, these came from the

local Autozone or Advanced Auto Parts store. For the remainder of the fuel

system, steel lines were used with

either the special fuel injection hose or braided steel hose and dual

gates clamps at any location where flex is required. The braided stuff

was used on the pressure side and hose on the return side. This should

be overkill, but I'd rather err on the safe side.

The new plumbing tucks nicely under the air cleaner. A little paint

to the air cleaner and she'll be good as new. The throttle cable

was no longer available from GM. I opted for the long braided steel universal

street rod cable from Lokar--which is still a bit on the short side. I

still have no idea what the bracket looks like either. I made one out of

steel with the help of an Oxy-Acetylene torch.

Special Oxygen sensor bung$ are available from Jeg's and other places. I bought

a pair of anti-fouling 18mm spark plug adapters for $3 and cut off the

bottom with a hacksaw. After welding the bung into the header collector,

adding a coat of John Deere Muffler Paint, and screwing in the O2 sensor

I have something like this...

Installation and wiring of the ECM is an exercise in patience and details.

Painless Wiring

offers a wiring harness without all the extraneous wires which could make

this much easier...if you find writing the check to be easy. I cut a rectangular

hole in the firewall (ouch!) to accomodate the bulkhead connector of my

junkyard wiring harness and allow the ECM to be placed in the interior

of the car. The ALDL connector was mounted under the dash as GM intended

it.

It was quickly noted that I would have to install the VSS for proper

operation (the IAC resets itself when the car reaches 35mph--without this

your chances of ever idling are slim). While looking for the absolutely

quickest way out, I bought Painless Wiring's VSS for TBI cars. Part #60115

was expensive, but braindead easy to install. One day I'll get the

real thing and post an alternative to this pricey stuff.

The best solution for a fuel tank (and pump) would be to find a suitable

donor from a fuel injected car. These would have baffles and an in-tank

pump. I jerry-rigged a baffle for my tank and will share that only if it

turns out to be OK. Confidence in my rig is still low.

Copyright

This information is made available for personal use only and may not be

reproduced without written consent of the author(s). Any attempt to sell

or use this information for personal gain or business purposes is expressly

forbidden.